HMD SERIES

HMD Series Membrane Dryers

THE NEXT GENERATION IN MEMBRANE TECHNOLOGY

Advancements in design allow membrane technology to efficiently dehydrate compressed air. Versatile, environmentally and user-friendly, membrane dryers are the ideal solution for low flow and point of use applications.

카탈로그 다운로드

- Versatile

- Lightweight—can be installed without additional support

- Operates in both horizontal and vertical orientation

- Convenient mounting systems available

- High inlet and outlet flows

- Dryers may be sized to produce dew point temperatures from -40°F (-40°C) or below to +50°F (+10°C)

- Efficient

- Low sweep air rates — more air available downstream

- Choice of Prefilter packages:

- HF Series Grade 5 high efficiency oil removal filter for normal applications

- HF Series Grade 7 air linet filter and Grade 6 ultra high efficiency oil removal filter for critical applications

- Low Maintenance

- No power source required

- No moving parts to maintain, repair or wear out

- No consumables to replace

- No liquid condensate to dispose of

- Drying Protection

- Pressurized air is contained inside the membranes

- Housing contains air at atmospheric pressure

- No oil/water emulsions or chemicals to dispose of

- Durable Construction

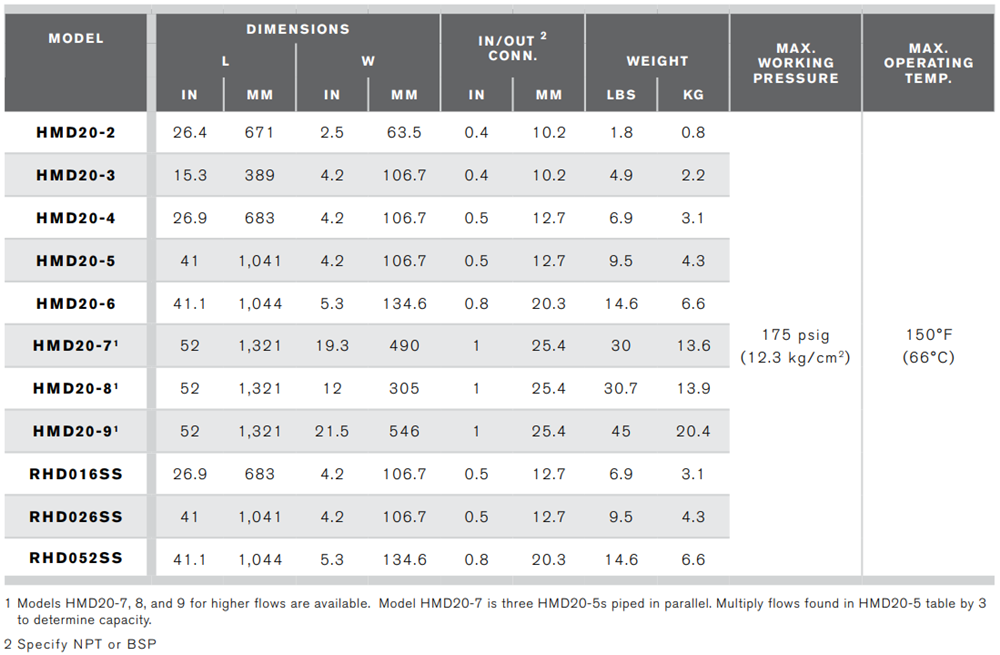

- Maximum working pressure for all models: 175 psig (12.3 kg/cm2)

- Maximum inlet temperature: 150°F (66°C)

How it Works

Compressed air, saturated with water vapor, flows through a bundle of tube-shaped hollow membrane fibers. A sweep orifice installed at the end of the bundle meters the amount of sweep air required to remove the water vapor from the dryer. Dry air then exits the tube bundle for use downstream. As long as the dried air isn’t exposed to temperatures below the specified pressure dew point, no troublesome liquid water will form in the air system.

Product Specifications

HMM SERIES

HMM Series Membrane Dryers

CONTINUOUS FLOW MEMBRANE DRYERS

HMM Series modular membrane compressed air dryers provide clean, dry compressed air wherever you need it.

Designed for continous dlow applications, HMM Series dryers pass a constant side-stream of dry sweep air to exhaust the extracted water vapor into the ambient sur-roundings.

- MODULAR HF SERIES AIR PREPARATION

- Operation requires the removal of contaminants like liquid water.

compressor lubricant, dust, rust, and pipe scale before entering the dryer. Clean, filtered, compressed air will rewald you with many years of satisfactory performance from you Modular Membrane dryer.

Simply select the series and model that meets your requirements, then, add the level of filteration you need.

FILTER PACKAGE RECOMMENDATIONS

| Application | Max. Liquid Inlet Content To Filter | Recommended HF Series Filtration |

|---|---|---|

| Space-sensitive OEM's & Pkgs. |

1,000 ppm w/W |

Prefillters : Grade 5 - 0.008ppm (0.01 mg/㎥) oil removal |

| General Industrial Point-of-use | 2,000 ppm w/W |

Prefillters : Grade 7 - 1 micron particulate Grade 3 - 0.0008ppm (0.001 mg/㎥) oil removal |

| Foods & Pharmaceuticuls Direct & Indirect air contact with air product | 2,000 ppm w/W |

Prefillters : Grade 7 - 1 micron particulate Grade 3 - 0.0008ppm (0.001 mg/㎥) oil removal Grade 1 - 0.003ppm (0.001\4 mg/㎥) oil removal |

TYPICAL APPLICATIONS

- Original Equipment Manufacturers (O.E.M.)

- NEMA 7 Hazardous Environments (HMM Series only)

- Paint spray Booths

- Dust Collectors

- Coordinate Measuring Machines

- Fluid Agitation

- Dental, Medical, Distilling, Photo Processing, Packaging, Graphic Arts, and Dry Cleaning Equipment

- Instrument Air

- Locomotive Air Brakes

- Oil & Gas Wells

- Ozone Generators

- Air Logics

- Rapid Transit Fare Collection Systems

- Air Blanketing

- Telephone Cable Pressurization

- Ship Supply Air

- Laboratory Instruments

- Control Panel Purge Air

- Optical Lens Cealing

- Laser Optics

- Welding Equipment

- Chemical and Gas Analyzers

- Dimensioning and Positioning Machines

- Product Fluidization