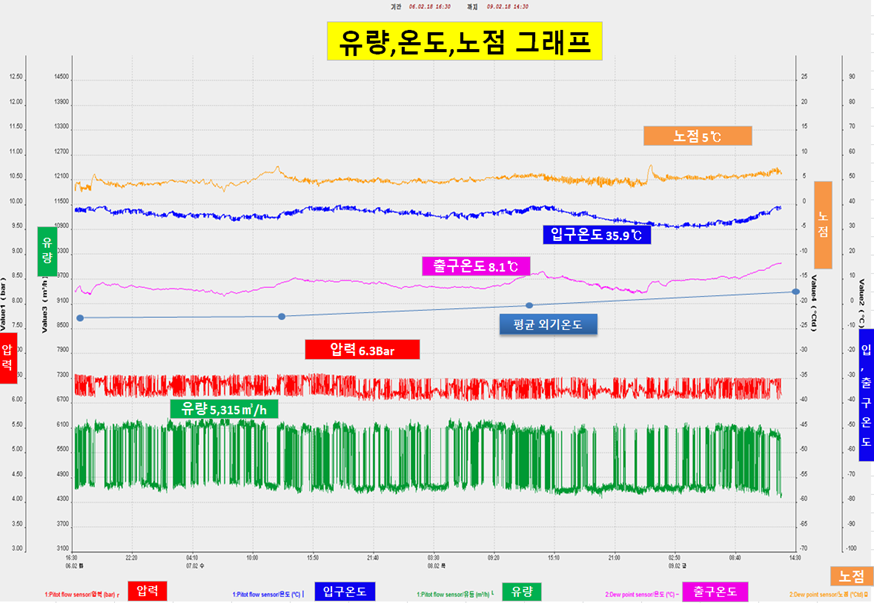

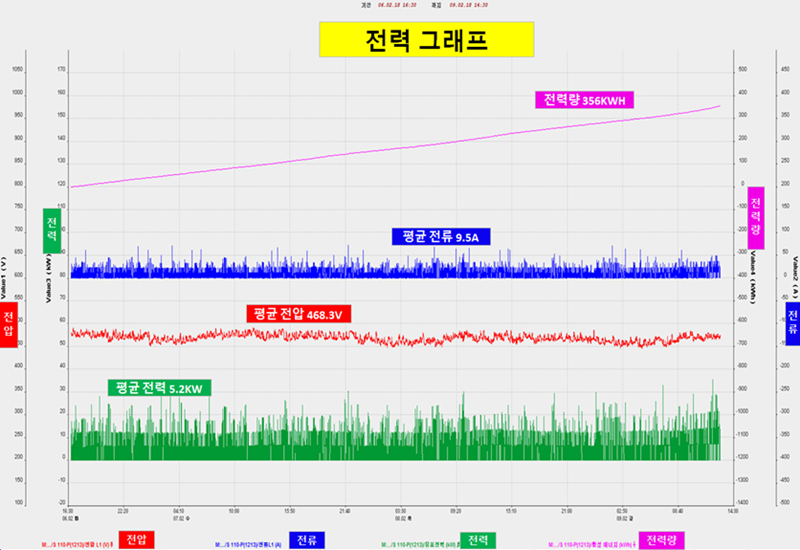

에너지관리 모니터링 및 진단

드라이어 에너지 절감의 진단 및 개조 Solution

- 1. 현황

- 신기술 도입 전의 산업현장에 설치된 드라이어는 노후 및 구태된 운전방식으로 인해 품질불량 및 높은 비용이 발생됩니다.

실제 사용되는 에어 유량이 얼마인지? 에어의 품질은 어떻게 되는지? 드라이어 유지비용은 어떻게 되는지?

드라이어의 실질적인 상태확인을 하지 않고서는 에어 품질 및 비용을 잡을수는 없습니다. ∴ Audit하지않은 귀사의 드라이어는 상당히 불합리하게 관리 되고 있습니다.

- 2. 대책

- 각 중요 부위에 검증된 계측설비를 바탕으로 전문 측정인원의 정확한 에어 상태 측정을 진행합니다.

이후 수집된 데이터를 바탕으로 고객께 현황 보고 및 방향성을 제시하여 품질향상 및 에너지 절감진행을 도모합니다.

- 3. 주요내용

- 냉동식, 흡착식 드라이어의 에어 계측 서비스 및 통합관리 보고

- 노후, 에너지 과사용 드라이어의 개조 및 설비개선

- 대형 플랜트 AIR 제습 관련 엔지니어링 기술 제공

S 551 COMPRESSED AIR ANALYZER

The ideal data logger for energy analyzes (ISO 50001) and air audits (ISO 11011)

- Easy to use

- Just connect the sensor and start the recording, no configuration and programming required

- Easy operation through color-touch display

- Flexible

- Connectable sensors for all required measurement tasks (air flow, air consumption, power consumption, pressure, temperature and many more)

- Up to 24 inputs through extension boxes and Modbus

- Several loggers can be combined: no need to have long cables from the sensor to the logger

- Third party sensors can be easily connected

- Safe

- Power glitches and cuts won‘t effect the performance: battery backup power

- Efficient

- S 551 does the job on the site

- Data analyzes in the office

- Price worthy solution

- Full software package includes:

- CSM-S for basic analyzes

- CAA for compressed air audit analyzes

Includes CS-iTEC Compressed Air Analyzer Software

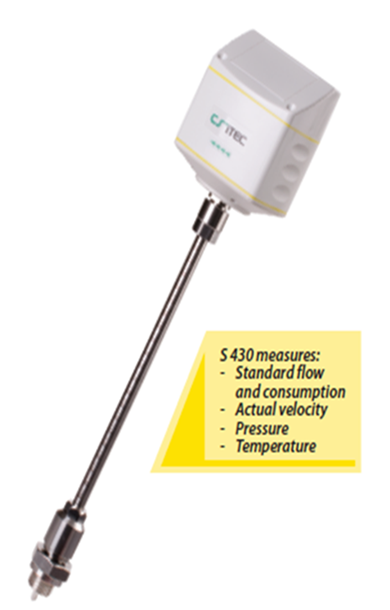

S 430 PITOT TUBE FLOW / CONSUMPTION SENSOR

S 430 is based on the pitot tube principle to measure flow.

Properly installed (refer to instruction manual for details) the sensor can measure in wet and dirty gases as occurring, for example, at the discharge of a compressor.

The sensor features long term stability, wide turn-down ratio and good temperature stability. It can be used in compressed air and non-corrosive gases.

Through a 1/2" G-type ball valve the sensor can be inserted into the pipe under pressure

Various output signals allow the sensor to be connected to CS-iTEC displays and/or third party displays and PLCs.

Color graphic display for online values and sensor settings

- Features

- Flow and consumption measurement in wet air or high mass flow / velocity applications

- Measurement at compressor outlet possible

- Tube diameters of 1’’ to 10” Other diameters on request

- Insertion type, easy installation under pressure through ball valve possible

- High temperature applications up to 200°C

- No mechanical wear parts

- All parts which are in contact with flow medium are made of stainless steel

| Technical Data S 430 | |

|---|---|

| Flow range | Refer to Instruction Manual |

| Pressure range | 0 ... 1.6MPa |

| Temperature range | -40℃ ... +200℃ |

| Accuracy | Flow : 0.5% F.S. Pressure : 0.5% F.S. Temperature : 0.5℃ |

| Pipe diameters | DN 25 (1") up DN 250 (10") |

| Reference conditions | Programmable, default P = 1000hPa, T = 20℃ |

| Medium | Wet and dry air and non-corrosive gases |

| Output signals | SDI (CS-iTEC : specific) 4 ... 20 mA and Pulse (optional) Modbus/RTU (optional) MBUS (optional) |

| Medium temp. | -40℃ ... +200℃ |

| Ambient temp. | -20℃ ... +60℃ |

| Operating pressure | 0 ... 1.6MPa |

| Power supply | 24 VDC, 150mA |

| Display option | 2.4" color graphics displays with keypad |

| Process connection | 1/2"G type |

Sensor tip with the two openings for pressure detection

M12 connectors at the back

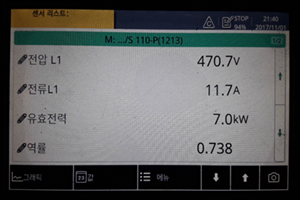

S 110 POWER METER

S 110 hat rail mountable

S 110-W in wall mountable casing

The SUTO Power Meters ares designed for easy installation and high accuracy. It measures the power consumption in KW and accumulates the Energt consumption in KWh of a 3-phase load. Additionally other measured parameters such as current, voltage,

and power factor etc. are available as well.

Through 3 clamp sensors the current is sensed. Hat rail, wall mountable and portable versions are available.

S 110-P, for connection to S 551

| Technical Data S 110 | |

|---|---|

| Nominal voltage(L-N, L-L) | 227 / 480 V AC |

| Clamp sensor input range | 0...1 A |

| Available clamp sensor | 200 A, 500 A, 1000 A |

| Power range | Up to 690 kw (depending on clamp sensor) |

| Accuracy | Voltage : 0.2% Current : 0.5% Clamp : class 1 Energy : class 0.5 |

| Output | Modbus / RTU |

| Supply | 24 V DC / 0.5 W |

| Operating Tem peratur | -5℃ .... +55℃ |

| Dimensions | Hat rail version : 110 X 90 X 31 mm Wall version : 190 X 155 X 60 mm Portable : 177 X 177 X 60mm |

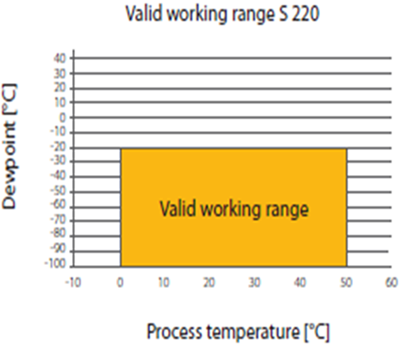

S 220 DEW POINT SENSOR (-100º ... 0ºC)

The SUTO dew point sensor S 220 provides reliable and long term stable dew point monitoring in industrial applications.

SUTO is using a new sensor technology which has superior signals at very low moisture levels thus providing reliable measurements

down to -100°C.

A stainless steel sinter filter with pore sizes below 30 μm protects the sensor from particles. It’s designed for applications where very low moisture levels needs to be detected.

The measured dew point is output through a 4-20 mA signal (3-wire or loop powered). Sensor parameters such as analogue output scaling, physical units, can be easily changed by using SUTO service kit.

- Features

- Very fast response time ensures safe and reliable indication whenever dew points are out of valid ranges

- Small size makes it ideal for dryer installations

- Measures dew points down to -100°C

- SUTO QCM sensor technology

- Version with integrated pressure measurement

- Various output versions available: 1 x 4 ... 20 mA, 2 x 4 ... 20 mA, RS-485 (Modbus), 4 ... 20 mA loop powered

- IP65 casing provides robust protection in rough industrial environment

- Can be installed directly into dryers through G 1/2” thread

- High accuracy of ±2°C dew point

- M12 connector

| Technical data S 220 | |||

|---|---|---|---|

| Measuring range | Dew point : -100 ... 0℃ Temperatur : -30 ... +70℃ Pressure : 0.05bar |

Accuracy | Dew point : 2℃ Temperatur : 0.3℃ Pressure : 0.05bar |

| Pressure range | -0.1 ... 1.6MPa (model 0699 0223 and 0699 0224) -0.1 ... 5.0MPa (all other models) -0.1 ... 35MPa (optional on request) |

Power supply | 12 ... 30VDC / 30mA |

| Measured gas | Non-corrosive gases | Ambient conditions | 0 ... 50℃ |

| Transport temperature | -30 ... +70℃ | Response time [90%] (at 4 l/min, perforated cap) | -80 ... -20℃ : 20 sec -20 ... -80℃ : 3 min |

| Output signal | 4 ... 20mA, 3wire (0699 0220, 0699 0221, 0699 0223) Modbus / RTU (0699 0222, 0699 0224) Loop powered 4_20 mA (0699 0025) |

Analog output scaling | 4 mA --> -100℃ 20 mA --> +20℃ |

| Connecrtor | M12, 5 pole | Wire sizes | Connector terminals support 0.14 ... 0.75㎟ |

| Casing | Process connection : stainless steel Casing : zinc alloy |

Classification | IP65 |

| Process connection | G 1/2" thread (ISO 228/1) | Sensor protection | A : stainless steel sinter filter, pore size

< 30μm B : Perforated sensor cap (standard, required a prefilter 0.1μm) |

| EMC | According to IEC 61326-1 | ||